In the last article we had a brief introduction to Shaken and why cars that have recently passed Shaken are good candidates for export. The last article also introduced the Shaken Self-Inspection also started going in depth on the items the owner is required to check on the Shaken Self-Inspection before even taking the vehicle to the Shaken Station. This article will finish the in depth look at the Shaken Self-Inspection. Japanese auto owners often have a mechanic do the Shaken Self-Inspection, which means that most vehicles are fully maintained and inspected by a professional at least once every two years. If you are looking for a well maintained JDM vehicle, Japan Car Direct can source one for you direct form dealer auctions and dealer lots across Japan.

Part IB: 60 part Shaken Self-Inspection 27-60 (Tenken Seibi Kirokubo):

- Covered in Shaken 1A

- Interior Inspection

- Steering Wheel

– Steering feel

– Steering wheel is rotated left and right to check for operating smoothness - Brake pedal

- Brake pedal play and depth

– Brake is depressed and distance to floor is measured. If during normal operation, brake depth is not too deep and brakes stop the car normally, it is probably ok.

– Notice: Bad brakes can cause a potentially life threatening situation for the driver, passengers and others. If you are unsure of your brake operation, please have them inspected by a professional. - Brake strength

– Brakes are depressed under speed and checked for left or right pull.

– During the Shaken inspection, brakes are checked by a rolling road and stop signal. The vehicle must be able to stop within an allotted time after the signal is lit.

- Brake pedal play and depth

- Parking brake

- Parking brake play

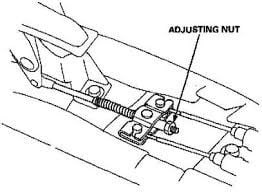

– Parking brake is pulled or depressed and the amount of play of the lever or pedal is measured. Anything more than 2-3 clicks should be adjustedParking brake adjustment

- Parking brake strength

– Parking brake is pulled or depressed and must keep the vehicle from moving

– During the Shaken inspection, parking brake is checked on a rolling road and stop signal. The vehicle must be able to stop within an allotted time after the signal is lit.

- Parking brake play

- Clutch pedal

- Clutch play and distance from floor

– Check distance from floor where clutch starts engaging. The clutch must not engage too close to the floor.

– Check clutch master cylinder, slave cylinder and hoses for leaks and wear

- Clutch play and distance from floor

- Steering Wheel

- Steering and suspension

- Alignment

- Alignment of the wheels and steering wheel

– When traveling straight, make sure that the top of the steering wheel is also at 12 o’clock.

- Alignment of the wheels and steering wheel

- Shock absorber

- Shock absorber damage and leaks

– Check the exterior of the shock absorbers for leaks and any damage. Also check shock boots for tears.

- Shock absorber damage and leaks

- Suspension

- Suspension attachment points, dents, damage, wear

– Check all attachment points for wear and damage

– All rubber bushings should be checked for deterioration

- Suspension attachment points, dents, damage, wear

- Wheels

- Tires

– Tire tread depth should exceed 1.6mm

– Tires should be checked for cracks and other deterioration - Lug nuts and studs

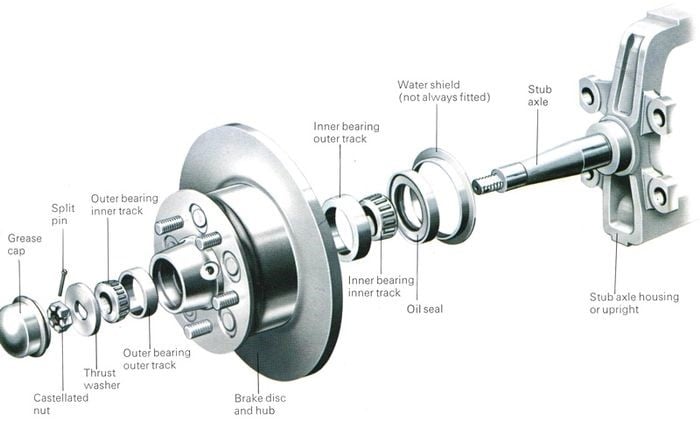

– Studs and lug nuts should be checked for tightness and wear - Front wheel bearings

– Jack up front of vehicle and wiggle front wheels to test for front wheel bearing wearFront hub components

- Rear wheel bearings

– Jack up rear of vehicle and wiggle rear wheels to test for rear wheel bearing wear

- Tires

- Brakes disks and drums

- Brake disk pad gap

– Place car on lift and rotate tire to check for brake pad drag and noise - Brake pad wear

– Check brake pads for remaining pad thickness.Brake Caliper and Pads

- Brake disk wear

– Brake disks should be check for minimum thickness, wear and warpin - Drum and drum shoe gap

– Place car on lift and rotate tires to check for drum shoe drag and noise - Brake shoe wear

– Check brake shoes for remaining pad thickness - Brake Drum wear

– Brake drums should be checked for minimum thickness and wear

- Brake disk pad gap

- Brake Master Cylinder, Wheel Cylinder and Brake Calipers

- Leaks

– Check brake system for leaks - Operation wear and damage

– Check brake system and attachment points for proper operation tightness, and any wear or other damage

- Leaks

- Alignment

- Undercarriage

- Steering Rack

- Attachment points

– Check steering rack attachment bolts and nuts for proper tightness and wear

- Attachment points

- Steering Rod and Arms

- Tightness, wear and damage

– Check steering rod and suspension arms for proper tightness and wear

- Tightness, wear and damage

- Ball joints

- Ball joint wear

– Check ball joints for wear, cracks and other damage

- Ball joint wear

- Transmission

- Oil leaks and level

– Check transmission for any leaks and check transmission fluid level and condition

- Oil leaks and level

- Drive shaft and Half Shafts

- Joints

– Check Universal Joints or CV Joints for wear or play - Boots

– Check drive shaft or half shaft boots for wear and grease leakageTorn CV boot

- Joints

- Differential

- Oil leaks and level

– Check Differential for oil leaks and level

- Oil leaks and level

- Parking brake lever or pedal and cables

- Brake Lever or Pedal and cable tightness, wear and damage

– Check parking brake components for tightness, wear and damage. Check parking brake cables for proper operation, wear, fraying and rust

- Brake Lever or Pedal and cable tightness, wear and damage

- Brake hose and pipes

- Leaks, wear and proper installation

– Check brake hoses and pipes for leaks, wear and proper installation

- Leaks, wear and proper installation

- Exhaust system

- Tightness and damage

– Exhaust pipes, mufflers and catalytic converter are checked for proper tightness and damage - Muffler

– Muffler is checked for proper operation - Heat shields

– Exhaust heat shields are checked for tightness and condition

- Tightness and damage

- Steering Rack

- Frame and Body

- Frame and Body

- Tightness and condition

– Frame and body of the vehicle should be checked for proper attachment and condition.

- Tightness and condition

- Frame and Body

The number and depth of the parts that need to be inspected keep the average vehicle in Japan in top working condition and maximize safety for the driver, passengers and others on the road. However, because most Japanese people lack the place or skill to be able to do the inspections on their own, they elect to have their vehicles looked at and inspected by a mechanic every two years before Shaken. We can locate a vehicle for you that has recently passed Shaken.

In Part 2, we will cover the actual Shaken Test!

Written By Yoshi